Navigating the Future: Trends Shaping Supply Chain Management in 2025

Related Articles: Navigating the Future: Trends Shaping Supply Chain Management in 2025

Introduction

In this auspicious occasion, we are delighted to delve into the intriguing topic related to Navigating the Future: Trends Shaping Supply Chain Management in 2025. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

- 1 Related Articles: Navigating the Future: Trends Shaping Supply Chain Management in 2025

- 2 Introduction

- 3 Navigating the Future: Trends Shaping Supply Chain Management in 2025

- 3.1 Key Trends Shaping the Future of Supply Chain Management

- 3.2 Related Searches:

- 3.3 FAQs:

- 3.4 Tips for Success in Supply Chain Management in 2025:

- 3.5 Conclusion:

- 4 Closure

Navigating the Future: Trends Shaping Supply Chain Management in 2025

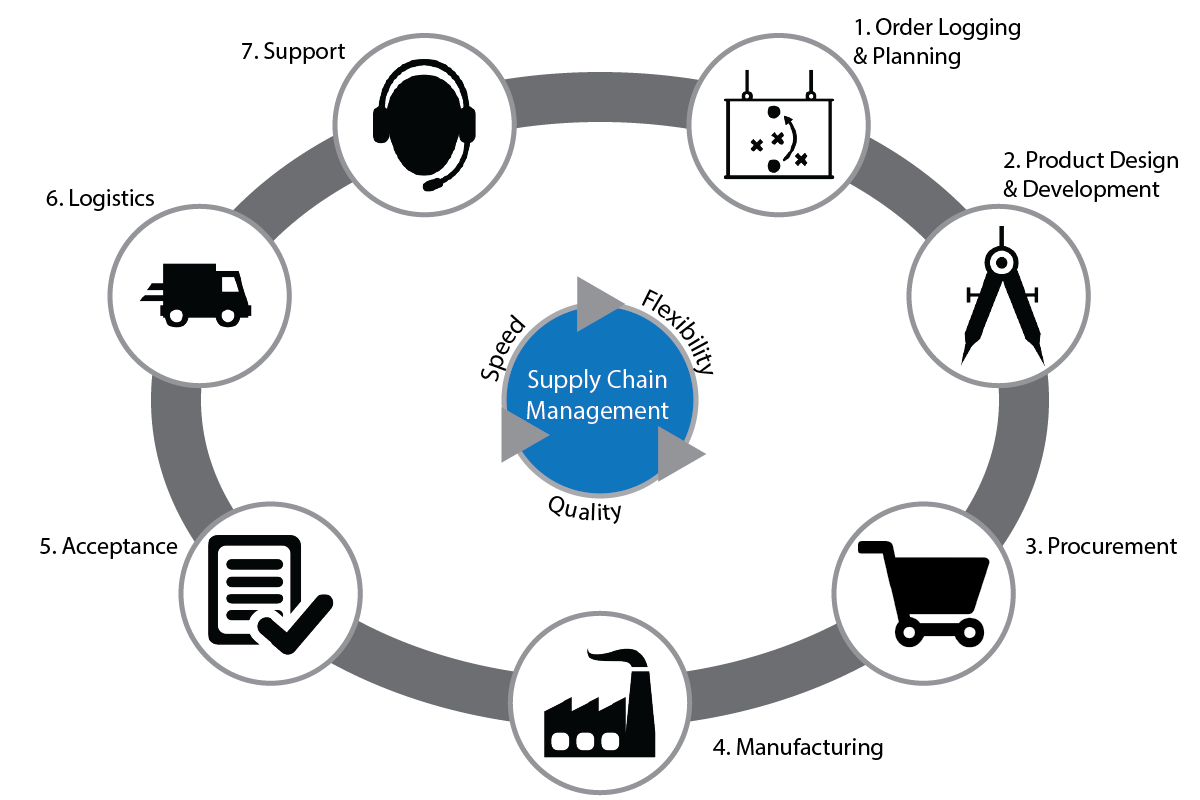

The global landscape is in constant flux, and the supply chain management (SCM) sector is no exception. As we approach 2025, several significant trends are poised to redefine the way businesses manage their intricate networks of suppliers, manufacturers, distributors, and customers. Understanding these trends and adapting to them will be crucial for businesses seeking to thrive in the increasingly complex and competitive market of the future.

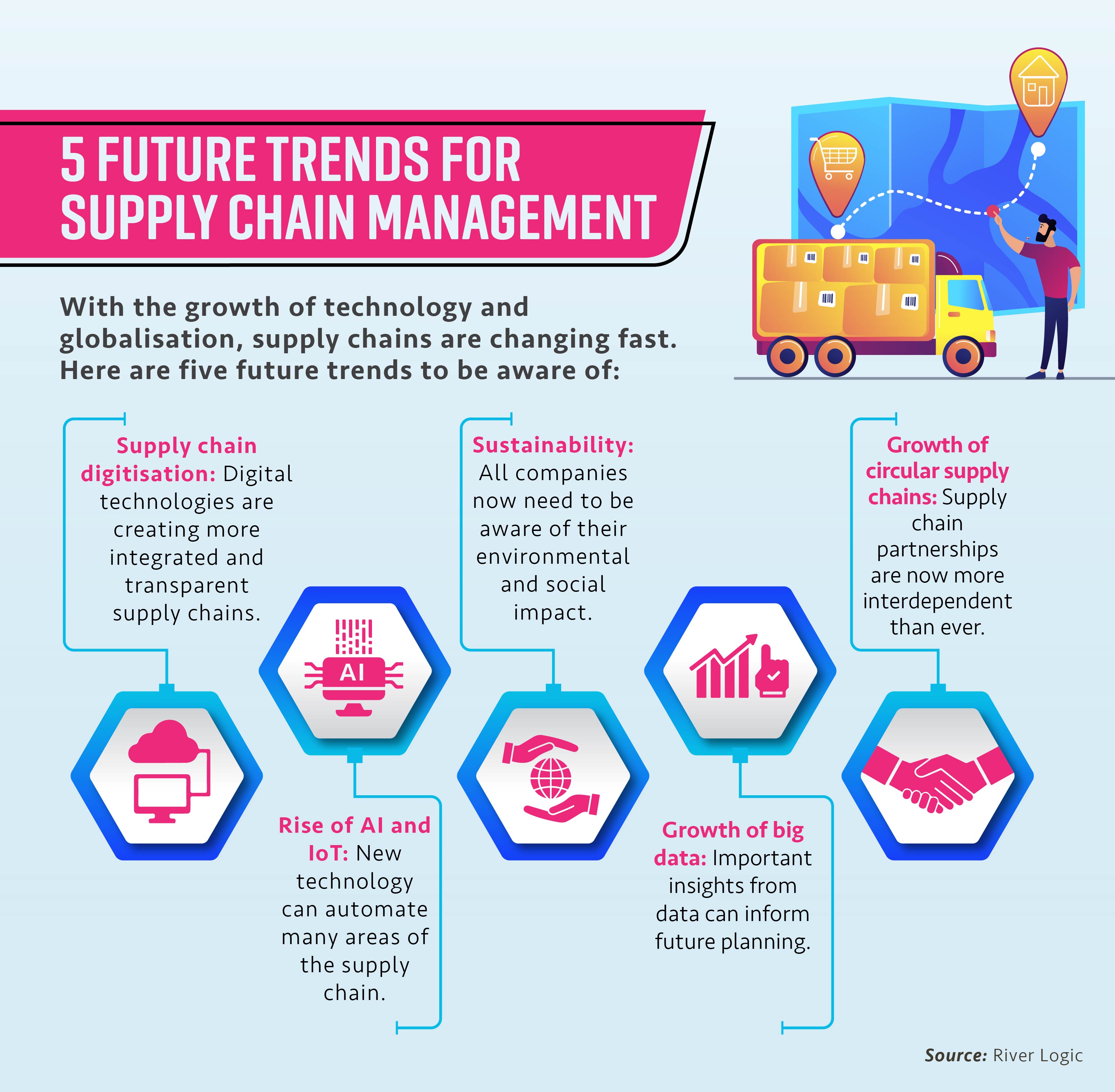

Key Trends Shaping the Future of Supply Chain Management

1. The Rise of Artificial Intelligence (AI) and Machine Learning (ML)

AI and ML are rapidly transforming the way businesses operate, and SCM is no exception. These technologies are being leveraged to automate tasks, analyze data, predict demand, optimize routes, and improve inventory management.

- Automated Forecasting: AI-powered forecasting systems can analyze historical data, market trends, and external factors to provide more accurate and timely demand predictions, enabling businesses to optimize inventory levels and reduce stockouts.

- Demand Planning: ML algorithms can analyze customer purchasing patterns, social media trends, and economic indicators to predict future demand, allowing businesses to proactively adjust production and distribution plans.

- Route Optimization: AI-powered route optimization software can analyze real-time traffic conditions, weather forecasts, and other factors to determine the most efficient delivery routes, reducing transportation costs and delivery times.

- Supply Chain Risk Management: AI can identify potential disruptions in the supply chain, such as natural disasters, political instability, or supplier failures, allowing businesses to proactively mitigate risks and ensure business continuity.

2. The Importance of Data and Analytics

Data is the lifeblood of any modern business, and SCM is no exception. The ability to collect, analyze, and interpret data is essential for making informed decisions, optimizing processes, and improving efficiency.

- Real-Time Visibility: Data-driven platforms provide real-time visibility into the entire supply chain, from raw materials to finished goods, enabling businesses to track inventory levels, monitor production schedules, and identify potential bottlenecks.

- Predictive Analytics: By analyzing historical data and identifying patterns, businesses can use predictive analytics to forecast future demand, optimize inventory levels, and anticipate potential disruptions.

- Supply Chain Performance Monitoring: Data analytics can be used to track key performance indicators (KPIs) such as delivery times, on-time delivery rates, and inventory turnover, allowing businesses to identify areas for improvement and measure the effectiveness of their supply chain strategies.

3. The Growing Importance of Sustainability

Sustainability is no longer a niche concern; it’s a core business imperative. Consumers are increasingly demanding eco-friendly products and services, and businesses are under pressure to reduce their environmental impact.

- Sustainable Sourcing: Businesses are actively seeking suppliers who adhere to ethical and sustainable practices, ensuring that their products are sourced responsibly and minimize environmental harm.

- Green Logistics: Businesses are investing in greener transportation options, such as electric vehicles and fuel-efficient delivery routes, to reduce their carbon footprint and minimize their environmental impact.

- Circular Economy: Businesses are exploring circular economy models, where products are designed for longevity, reuse, and recycling, minimizing waste and maximizing resource efficiency.

4. The Rise of the Digital Supply Chain

The digital transformation of the supply chain is accelerating, with businesses adopting cloud-based platforms, blockchain technology, and other digital tools to streamline operations and enhance collaboration.

- Cloud-Based Supply Chain Management Platforms: Cloud-based platforms provide a centralized hub for managing all aspects of the supply chain, from order management to inventory control to logistics.

- Blockchain Technology: Blockchain can be used to track products and materials throughout the supply chain, ensuring transparency, security, and traceability.

- Internet of Things (IoT): IoT devices can be used to monitor inventory levels, track shipments, and collect data on supply chain performance, providing real-time insights and enabling businesses to make more informed decisions.

5. The Growing Demand for Agility and Resilience

The global supply chain is becoming increasingly complex and volatile, with disruptions such as natural disasters, political instability, and pandemics posing significant challenges. Businesses need to be agile and resilient to adapt to these challenges and ensure business continuity.

- Supply Chain Diversification: Businesses are diversifying their supplier base to reduce their reliance on any single supplier and mitigate risks.

- Nearshoring and Reshoring: Businesses are bringing production closer to their customers or relocating manufacturing facilities back to their home countries to reduce lead times and improve responsiveness.

- Scenario Planning: Businesses are developing contingency plans for various disruptions, such as natural disasters, pandemics, or political instability, to ensure business continuity and minimize the impact of unforeseen events.

6. The Importance of Collaboration and Partnerships

Collaboration and partnerships are essential for navigating the complexities of the modern supply chain. Businesses need to work closely with their suppliers, distributors, and customers to improve efficiency, reduce costs, and enhance customer satisfaction.

- Supplier Relationship Management: Businesses are investing in building strong relationships with their suppliers, fostering collaboration, and sharing best practices.

- Third-Party Logistics (3PL) Providers: Businesses are increasingly relying on 3PL providers to manage logistics, warehousing, and transportation, allowing them to focus on their core competencies.

- Customer-Centric Supply Chains: Businesses are designing their supply chains with customer needs in mind, focusing on providing personalized experiences and meeting customer expectations for speed, convenience, and transparency.

7. The Growing Importance of Workforce Development

The skills gap in SCM is widening, and businesses need to invest in training and development to equip their workforce with the skills and knowledge needed to navigate the complexities of the modern supply chain.

- Digital Skills: Businesses need to invest in training their workforce in digital skills, such as data analysis, cloud computing, and blockchain technology.

- Supply Chain Management Expertise: Businesses need to attract and retain talent with expertise in supply chain management, logistics, and operations.

- Leadership Development: Businesses need to develop leaders who can effectively manage complex supply chains, foster collaboration, and drive innovation.

8. The Rise of Omnichannel and Direct-to-Consumer (D2C) Models

The rise of e-commerce and the growing demand for personalized experiences are driving the adoption of omnichannel and D2C models. Businesses need to adapt their supply chains to meet the needs of these new models.

- Flexible Fulfillment Networks: Businesses need to build flexible fulfillment networks that can handle orders from multiple channels, including online, mobile, and physical stores.

- Last-Mile Delivery Optimization: Businesses need to optimize their last-mile delivery operations to ensure timely and efficient delivery of goods to customers.

- Customer Experience Management: Businesses need to focus on providing a seamless and personalized customer experience across all channels.

Related Searches:

1. Supply Chain Management Software

Supply chain management software is essential for businesses looking to streamline their operations, improve efficiency, and gain real-time visibility into their supply chains. These software solutions offer a wide range of features, including order management, inventory control, warehouse management, transportation management, and analytics.

2. Supply Chain Risk Management

Supply chain risk management is crucial for businesses seeking to identify and mitigate potential disruptions that could impact their operations. This involves assessing potential risks, developing mitigation strategies, and implementing robust risk management frameworks.

3. Supply Chain Analytics

Supply chain analytics involves collecting, analyzing, and interpreting data to gain insights into supply chain performance, identify areas for improvement, and make data-driven decisions. This includes using tools such as predictive analytics, data visualization, and machine learning.

4. Supply Chain Optimization

Supply chain optimization involves identifying and implementing strategies to improve efficiency, reduce costs, and enhance customer satisfaction. This includes optimizing inventory levels, transportation routes, and production processes.

5. Supply Chain Automation

Supply chain automation involves using technology to automate tasks and processes, such as order fulfillment, inventory management, and transportation. This can improve efficiency, reduce errors, and free up staff to focus on more strategic tasks.

6. Sustainable Supply Chain Management

Sustainable supply chain management involves incorporating environmental, social, and governance (ESG) considerations into all aspects of the supply chain, from sourcing to production to distribution. This includes reducing carbon emissions, minimizing waste, and promoting ethical labor practices.

7. Supply Chain Design

Supply chain design involves creating a network of suppliers, manufacturers, distributors, and customers that can meet the needs of the business and its customers. This includes considering factors such as location, transportation, capacity, and cost.

8. Supply Chain Transformation

Supply chain transformation involves fundamentally changing the way a business manages its supply chain, often involving the adoption of new technologies, processes, and strategies. This can be a complex and challenging process, but it can also lead to significant improvements in efficiency, cost-effectiveness, and customer satisfaction.

FAQs:

1. What are the biggest challenges facing supply chain management in 2025?

The biggest challenges facing SCM in 2025 include:

- Geopolitical Uncertainty: Global events such as trade wars, political instability, and pandemics can disrupt supply chains and create uncertainty for businesses.

- Supply Chain Disruptions: Disruptions such as natural disasters, labor shortages, and transportation bottlenecks can lead to delays, shortages, and increased costs.

- Cybersecurity Threats: Cyberattacks can disrupt supply chain operations, compromise sensitive data, and damage brand reputation.

- Talent Shortages: The growing demand for skilled SCM professionals is creating a talent shortage, making it challenging for businesses to find and retain qualified employees.

- Sustainability Concerns: Businesses face increasing pressure to operate sustainably, reducing their environmental impact and promoting ethical labor practices.

2. How can businesses prepare for the future of supply chain management?

Businesses can prepare for the future of SCM by:

- Investing in Technology: Businesses should invest in technologies such as AI, ML, cloud computing, and blockchain to improve efficiency, gain real-time visibility, and mitigate risks.

- Embracing Data-Driven Decision Making: Businesses should leverage data and analytics to make informed decisions, optimize processes, and improve performance.

- Focusing on Sustainability: Businesses should prioritize sustainability in their supply chains, reducing their environmental impact and promoting ethical labor practices.

- Developing a Resilient Supply Chain: Businesses should develop contingency plans and implement strategies to mitigate risks and ensure business continuity in the face of disruptions.

- Building Strong Partnerships: Businesses should cultivate strong relationships with suppliers, distributors, and customers to foster collaboration and improve efficiency.

- Investing in Workforce Development: Businesses should invest in training and development to equip their workforce with the skills and knowledge needed to navigate the complexities of the modern supply chain.

3. What are the benefits of adopting these trends in supply chain management?

The benefits of adopting these trends in SCM include:

- Improved Efficiency: Businesses can streamline operations, reduce costs, and increase productivity by automating tasks, optimizing processes, and leveraging data-driven insights.

- Enhanced Visibility: Businesses can gain real-time visibility into their supply chains, enabling them to track inventory levels, monitor production schedules, and identify potential bottlenecks.

- Increased Agility and Resilience: Businesses can adapt to disruptions, mitigate risks, and ensure business continuity by diversifying their supplier base, implementing contingency plans, and embracing digital technologies.

- Improved Customer Satisfaction: Businesses can provide a more personalized and seamless customer experience by leveraging omnichannel and D2C models, optimizing last-mile delivery, and focusing on customer feedback.

- Enhanced Sustainability: Businesses can reduce their environmental impact, promote ethical labor practices, and enhance their brand reputation by incorporating sustainability considerations into their supply chains.

Tips for Success in Supply Chain Management in 2025:

- Embrace Digital Transformation: Businesses should embrace digital technologies such as AI, ML, cloud computing, and blockchain to streamline operations, improve efficiency, and gain a competitive advantage.

- Prioritize Data and Analytics: Businesses should leverage data and analytics to gain insights into supply chain performance, identify areas for improvement, and make data-driven decisions.

- Build a Strong Supplier Network: Businesses should cultivate strong relationships with their suppliers, fostering collaboration, and sharing best practices.

- Develop a Robust Risk Management Framework: Businesses should identify and assess potential risks, develop mitigation strategies, and implement robust risk management frameworks to ensure business continuity.

- Invest in Workforce Development: Businesses should invest in training and development to equip their workforce with the skills and knowledge needed to navigate the complexities of the modern supply chain.

- Focus on Sustainability: Businesses should incorporate sustainability considerations into all aspects of their supply chains, reducing their environmental impact and promoting ethical labor practices.

- Stay Agile and Adaptable: Businesses should be prepared to adapt to changing market conditions and embrace new technologies and trends.

Conclusion:

The SCM landscape in 2025 will be characterized by rapid technological advancements, increasing complexity, and a growing focus on sustainability. Businesses that embrace these trends, invest in technology, and develop a resilient and agile supply chain will be well-positioned to thrive in the future. By focusing on innovation, collaboration, and sustainability, businesses can navigate the complexities of the modern supply chain and achieve success in the years to come.

95db7b.jpg)

Closure

Thus, we hope this article has provided valuable insights into Navigating the Future: Trends Shaping Supply Chain Management in 2025. We thank you for taking the time to read this article. See you in our next article!